how does vapor honing work

On aluminum it leaves a finish that looks almost like paint. Vapor honing is also a great choice for removing very tiny scuffs and tool marks as well as for applications that need a satin-smooth finish.

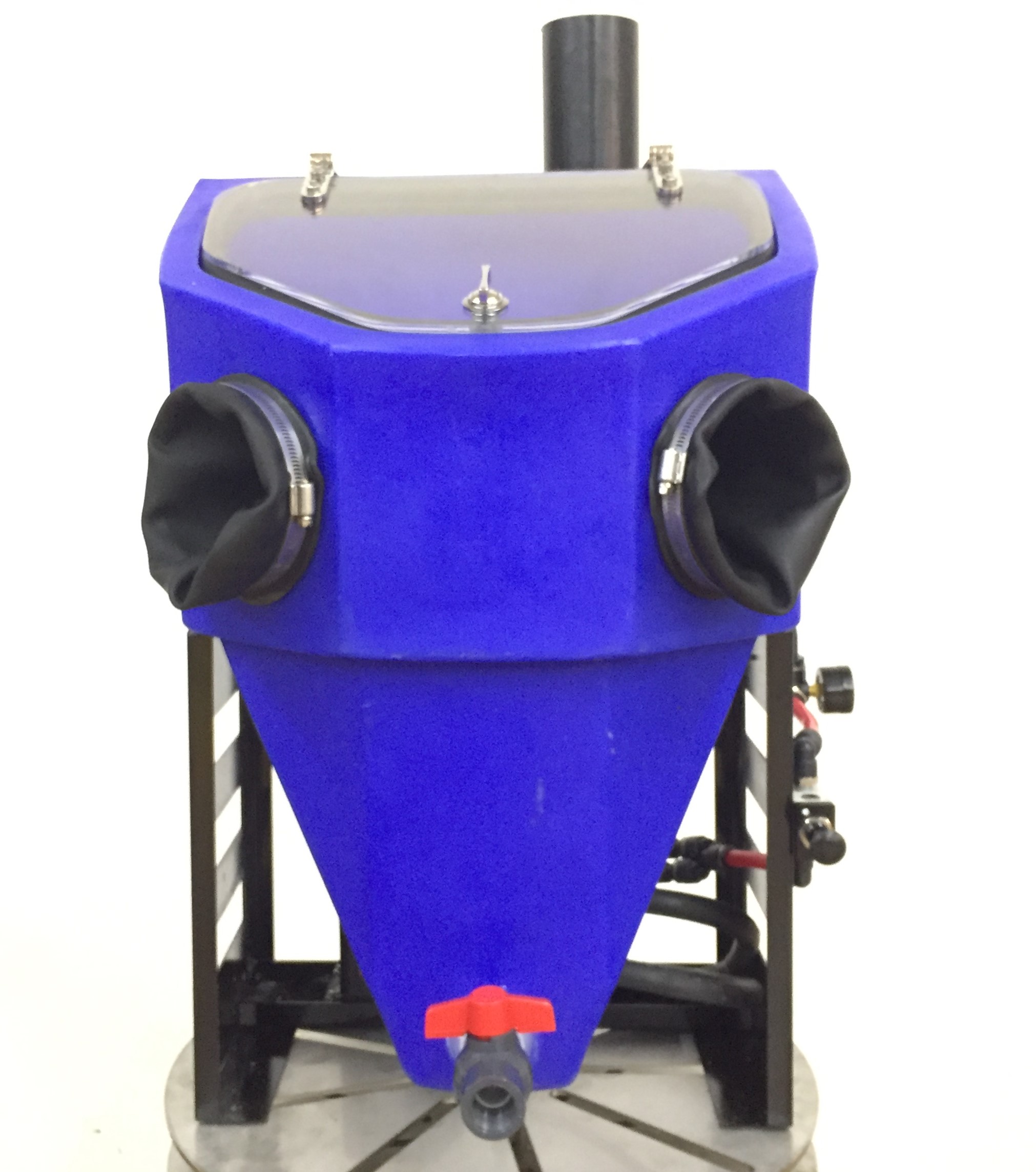

Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa

This involves blasting water and compressed air against a surface in order to clean it.

. Vapor blasting is the combination of mixing water with abrasive which forms a slurry. Vapor honing is a wet blasting process which uses very fine glass beads and water under air pressure. It does this by blasting the object with a mixture of air water and detergents and semi-rough cleaning media.

Vapor honing smooths surfaces with the use of abrasive media and water. The liquid is pumped up to the blasting gun and compressed air accelerate the mixture propelling it towards the part. Combine water and the abrasive for your application and you are ready to begin blasting.

In this way how does Vapour blasting work. Vapor honing uses water and abrasive flowing across the surface to scrub away contaminates rather than directly impacting the surface damaging and removing material. Vapor Honing often known as wet blasting is a technique used to polish precise surfaces.

Call or email Vapor Honing Technologies for more informat. Water abrasive and compressed air are 3 key components to vapor abrasive blasting. Sandblasting on the other hand restores surfaces with the use of impacts and sheer force.

To remove imperfections such as heat treat scaling you add fine abrasives to the water then sprayed onto the material at great speed. This slurry is mixed into a fluid and evenly mixed as a liquid in the bottom of the hopper. Vapor Honing Technologies has assisted thousan.

You may already be familiar with the concept of vapor blasting even if you dont know it by this name. While it can handle a wide variety of materials it gives a excellent finish aluminum zinc brass and magnesium. Dont be afraid to color outside of the lines and think for yourself.

This treatment is typical of a conventional dry blasting procedure. What is vapor honing. Vapor honing can be used on almost any surface found on a motorcycle or car including gloss plastic.

Wet blasting vapor blasting is a process for removing contaminants from a surface or finishing a surface. Are favorite application is carbs for the finish it provides. Depending on your application this will determine your abrasive needed to process your parts.

It leaves a smooth satin finish and is much more gentle to the surface than dry sand or glass bead blasting. How Does Vapor Honing Work. We normally refer this as the sump.

Makes your old parts look like new. Its perfect for restoration work because it makes the metal surface look like new but does not remove metal like. No need to worry a.

For this reason vapor honing eliminates negative characteristics such as media impingement. The video talks a little bit about the Vapor Honing Process and What makes it unique and different. Click to see full answer.

The key to vapor blasting is that the finish is produced through the flow of water borne abrasive giving a finer finish due to the flushing action of the water. Vapor honing also referred to as vapor blasting or wet blasting is a surface refinishing process used to clean and restore surfaces. Then you can insert the part through the side door of your vapor honing cabinet.

You will have to play with the setting and see what makes it work best for you. There are hundreds of different applications and abrasive mixtures that can be combined to. Vapor Honing a carburetor body is one of hundreds of applications that a vapor honing cabinet can be used for.

Vapor honing is also known as vapor blasting aqua blasting wet blasting slurry blasting and dustless blasting. No media is impregnated into the component nor is there any dust created by the break-up of media unlike dry blasting where the finish is produced by sheer force of media impact. Vapor honing is a non-abrasive form of cleaning meaning that it poses no risk to the object thats being cleaned.

It is also known as wet blasting vapor honing and dustless blasting. Vapor honing also referred to as vapor blasting or wet blasting is a surface refinishing process used to clean and restore surfaces. Instead of dry abrasive media used in sandblasting it uses a combination of water compressed air detergents with finer and gentler media to remove oxidized metal and corrosion.

Basically this is a technology that involves the blasting of abrasive material blast mixed with pressurized water. Water abrasive and compressed air are 3 ke. Nonetheless its effective for removing both oxidization and corrosion.

Before you start the cleaning process you need to pick the type of abrasive youll use to clean your part. As you can see from all these names vapor honing is the wet version of dry blasting.

Vapor Blasting Services Wet Blasting Vapor Honing Technologies

Cleaning Pistons Using Vapor Blasting Vapor Honing Technologies Youtube

Vapor Honing Wet Blasting Vapor Blasting Blast Wash Systems

What Exactly Is Vapor Honing 5 Things You Should Know

Vapor Honing An Engine The Ultimate Guide

A Simple Introduction To Vapor Honing Issuu

Vapor Hone Up And Running Bike Builds Motocross Forums Message Boards Vital Mx

What Is Vapor Blasting Answering Your Wet Blasting Faqs

Micro Vapor Hone Benchtop Vapor Hone With A Small Footprint

Slurry Blasting Vapor Blasting Equipment For Sale Vapor Honing Technologies

Vapor Honing Technologies Lilhonda Com

How Good Is The Micro Hone Vapor Honing Technologies Youtube

Vapor Blasting What It Is Costs And Shipping

Vapor Hone 1000 Wet Blasting Equipment Blast Wash Systems

Rust Removal With Vapor Honing Vapor Honing Technologies Youtube